Understand the technology behind SMD modules

What is SMD LED?

Surface-mounted device or SMD LED is a revolutionary technology in LED displays. Unlike traditional LEDs, SMD LEDs are small, flexible, and are directly attached to a printed circuit board (PCB). They come in various sizes and can be any color, so many applications to choose from.

For example, think of the difference between an old light bulb and an LED strip. Like the latter, the SMD LED is thin, energy-efficient, and able to fit in smaller areas. This is important in modern design where form and function go together.

So, how do SMD LEDs work? They use a semiconductor material that converts electrical energy into light. When an electric current passes through the diode, it excites the electrons and they emit photons – light. This is efficient and produces less heat than traditional incandescent bulbs, that’s why SMD LEDs are popular.

SMD LED Features

In the previous section, we explained the general concept of SMD LEDs, now let’s go into the details.

- Small: SMD LEDs are designed to take up less space, perfect for modern electronics where space is tight.

- Efficient: They have high luminous efficiency and more light output with less energy consumption.

- Easy to Integrate: Surface mount technology allows for faster and more efficient assembly on PCBs.

- Heat Management: SMD LEDs have built-in heat sinks, so they won’t overheat.

- Directionality: SMD LEDs are more effective in lighting applications when they are made to emit light in particular directions.

You may ask how these tiny components can fit into displays. The simplicity of SMD LED integration is because they can be mounted directly onto printed circuit boards (PCBs). This makes the manufacturing process easier and more durable.

How Do SMD LED Displays Work?

Surface-Mount Device Light Emitting Diodes (SMD LEDs) are used in SMD LED displays to provide high-resolution images in a small, energy-efficient device. Three diodes—red, green, and blue—combined into a single tiny unit make up each SMD LED in the display. By adjusting the intensity of these three diodes the SMD LED can produce a wide range of colours which is required to produce detailed full-color images and videos.

Here’s the breakdown of the components and processes that make SMD LED displays work:

1. SMD LED Structure

- SMD LED means LEDs mounted directly on a circuit board, with no wire leads.

- Because SMD LEDs have many color diodes (typically RGB) in a single chip, they may combine red, green, and blue lights in varying intensities to produce a wide color spectrum.

- This is what makes SMD displays have smaller pixel pitch and higher resolution than traditional DIP LED technology.

2. Pixel and Color

- Each SMD LED in the display is a “pixel”. By combining multiple SMD LEDs in a grid, these displays can produce detailed color-accurate images.

- Colors are achieved through additive color mixing, where the intensities of the red, green, and blue diodes are adjusted to produce the desired color in each pixel.

- For example, by setting all three colors to full intensity the pixel appears white. By adjusting them individually a wide color range is possible, so SMD LED displays can produce vivid lifelike visuals.

3. Compact and High Resolution

- Because SMD LEDs are small, they can be packed closely together on the display board, resulting in a smaller “pixel pitch”. Pixel pitch is the distance between the centers of two adjacent pixels and determines the resolution of the display.

- The smaller the pixel pitch, the higher the resolution, so SMD LED displays are perfect for environments that require detailed imagery such as digital billboards, retail displays, and indoor advertising.

4. Power Efficiency and Heat Management

- Because SMD LEDs turn the majority of electrical energy into light rather than heat, they use less power and don’t overheat.

- Displays are designed with built-in heat dissipation mechanisms such as aluminum backings or heat sinks to ensure longevity and maintain optimal performance.

5. Seamless and Flexible

- SMD LED displays are designed to be versatile. They can be mounted on flexible or rigid substrates so the display can be curved or customized for unique installations.

- These displays are also modular so they can be scaled up by connecting multiple SMD panels to create large video walls or dynamic outdoor advertising boards.

SMD LED Display Benefits

- High Resolution and Image Quality: Because of the small size of SMD LEDs, these displays can produce high-resolution images, perfect for applications where image quality matters most such as TV screens and professional presentations.

- Wide Viewing Angle: SMD LEDs have wide viewing angles so displays can be viewed from different angles without losing color accuracy or brightness—perfect for big audience visibility.

- Color Range: SMD LED displays can produce a wide range of colors by combining different semiconductor materials within each LED, so it’s suitable for any environment.

- Energy Efficiency: SMD LED displays consume less power than traditional displays so it’s cost-effective for large-scale installations like outdoor billboards which run 24/7.

- Durability and Long Life: Built with rugged materials, SMD LED displays can withstand different environmental conditions so it’s a long-term solution for indoor and outdoor applications.

Applications of SMD LED Displays

SMD LED displays are used in various industries:

- Digital Signage: Bright and attention-grabbing SMD LED displays for advertising and information dissemination in high foot traffic areas.

- Entertainment Venues: Clear and immersive visuals for concerts, sports events, and theaters.

- Retail and Hospitality: Stores and hotels use SMD LED displays for attractive and customizable interior visuals to enhance customer experience.

- Control Rooms and Command Centers: High-resolution SMD LED displays ensure clear data visualization, enabling accurate monitoring and decision-making.

SMD vs Other LED Displays

When choosing an LED display, you need to know how SMD (Surface-Mount Device) LED displays differ from other LED types, such as DIP (Dual In-line Package) LED and COB (Chip-on-Board) LED displays. Each has its own features, benefits, and applications. Here’s a comparison of SMD LED displays with DIP and COB to help you decide which one is best for your project:

DIP LED vs SMD LED Screen

DIP or Dual In-Line Package LEDs have two lead wires connected to each LED, making a bigger structure that’s mounted on a PCB. Each DIP LED pixel consists of three individual LEDs (red, green, blue) arranged separately.

Pros:

- Extremely Bright: DIP LEDs are very bright and good for outdoor applications that need to compete with sunlight.

- Durable: DIP displays are rugged, can withstand harsh weather, and are often waterproof, good for outdoor installations.

- Cost Effective for Big Scale: For larger screens with wider pixel pitches, DIP displays are more cost-effective.

Applications: Outdoor displays like billboards, stadium screens, and large format advertising where viewing is from a distance and brightness is key.

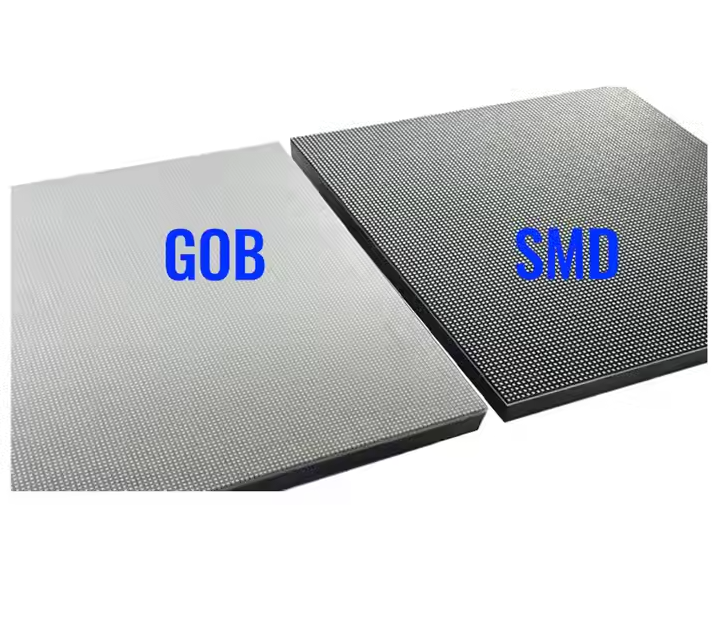

COB LED Screen vs SMD LED Screen

Multiple LED chips are positioned directly onto a substrate in COB displays, creating a more cohesive light source with fewer diode gaps. This results in a smoother appearance and less pixelation.

Pros:

- Compact and Light: COB displays are more compact and light because of the single unit design, easier to install and transport.

- Uniform Brightness: They provide smooth and even brightness across the screen, good for environments where even light distribution is critical.

- Heat Dissipation: The substrate of COB LEDs helps to dissipate heat, and longer display life.

Applications: Indoor and outdoor applications where high brightness, compactness, and durability are required. Used in stage displays, portable installations, and high-end retail displays.

Key Differences Summary

| Feature | SMD LED Display | DIP LED Display | COB LED Display |

| Pixel Pitch | Smaller, enabling high resolution | Larger, suitable for distant viewing | Medium, with less visible pixelation |

| Brightness | Moderate (high for indoor) | Very high, ideal for outdoor | High, consistent across the display |

| Viewing Angle | Wide | Narrower | Moderate |

| Durability | Suitable for indoor, some outdoor | Excellent for outdoor | Durable for both indoor/outdoor |

| Energy Efficiency | High | Moderate | High |

| Applications | Indoor displays, some outdoor | Large outdoor signage | Both indoor and outdoor applications |

Choosing Between SMD, DIP, and COB

- For Indoor, High-Resolution Displays: SMD is the way to go for high pixel density and color accuracy for retail signage, control rooms, and corporate environments.

- For Big, Outdoor Displays: DIP for large outdoor advertising that needs extreme brightness and durability.

- For Light, Flexible Solutions: COB for portable displays, stage backdrops, and compact installations where even brightness and weight savings are key.

Selecting the Right SMD LED Display

Choosing the right SMD LED display requires a closer look at several key factors to make sure it meets your environment and display requirements. Here’s a list of what to consider when choosing an SMD LED display.

Pixel Pitch and Resolution

- Pixel Pitch: Pixel pitch is the distance between the centers of two adjacent pixels on an LED display, measured in millimeters. This affects the resolution and viewing distance.

- Smaller Pixel Pitch: Higher resolution and more detailed visuals, for close-up indoor viewing, retail displays, or corporate environments.

- Larger Pixel Pitch: For long-distance viewing, stadiums, or billboards where viewers are further away.

- Resolution Needs: Higher resolutions are required for detailed imagery or text clarity, and lower resolutions for simple graphics or basic information displays.

Viewing Distance

The viewing distance is key in determining the right pixel pitch. As a rule:

- Close-Range Viewing: Smaller pixel pitches (1mm to 3mm) for sharp images.

- Medium-to-Long-Range Viewing: Larger pitches (4mm to 10mm) for displays that don’t need high detail.

Match the display’s pixel pitch to the average viewing distance for the best balance between clarity and cost.

Indoor vs Outdoor Use

- Indoor SMD Displays: Moderate brightness (600–1,500 nits) and tighter pixel pitch for high resolution. For controlled lighting environments like retail stores, conference rooms, and museums.

- Outdoor SMD Displays: Need higher brightness (up to 5,000 nits or more) to be visible in sunlight and weather resistant (IP65 or higher) to withstand rain, dust, and temperature changes.

Brightness Levels

Brightness is measured in nits and depends on the location and lighting conditions.

- Indoor Displays: 600-1,500 nits is enough for well-lit spaces.

- Semi-Outdoor/Window Displays: 1,500-3,000 nits to compete with indirect sunlight.

- Outdoor Displays: 3,000-5,000 nits for clear visibility in direct sunlight.

Some displays have auto brightness adjustments based on ambient light to save power and ensure visibility.

Budget and Installation Costs

- Initial Cost: Smaller pixel pitches, higher resolutions, and advanced features (like brightness sensors) cost more. Choose the highest resolution that fits your budget for the application.

- Installation Needs: Outdoor displays may require additional structural support and weatherproofing, indoor installations may have simpler mounting requirements.

Conclusion

SMD LED displays are a revolutionary technology in the world of visual displays. They combine compact size, energy efficiency, and brilliant image quality, making them a superior choice for both commercial and entertainment settings. With a wide range of applications and an array of design options, SMD LED displays provide a versatile, reliable, and visually impactful solution for modern display needs.